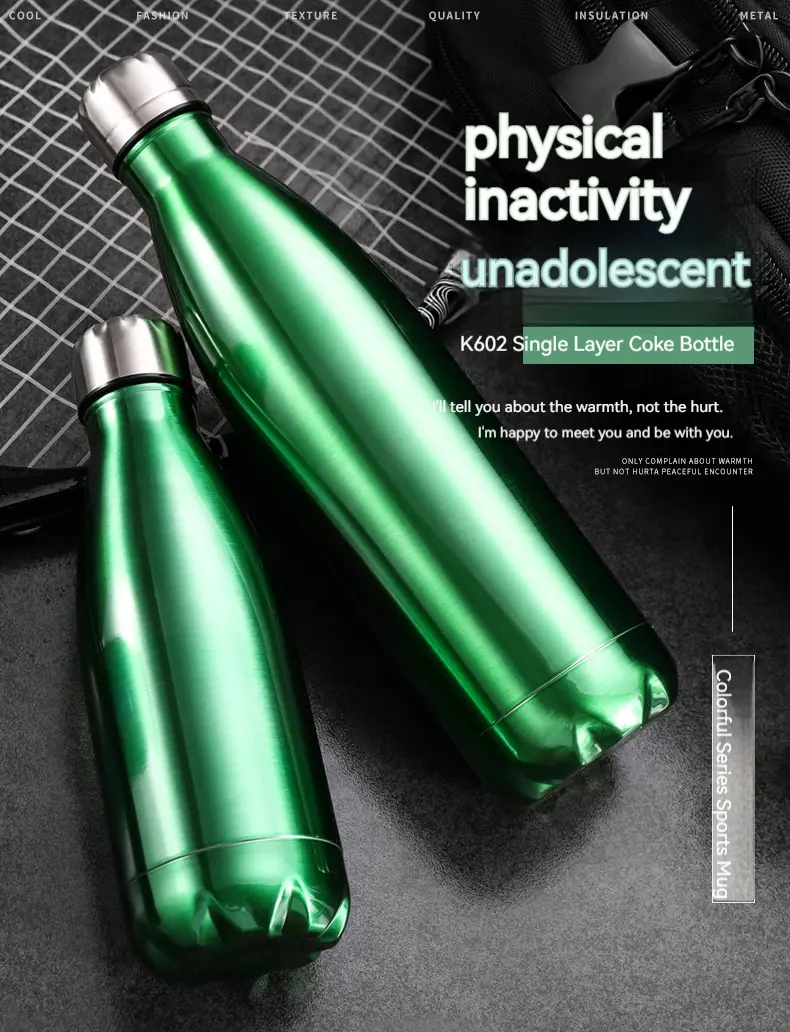

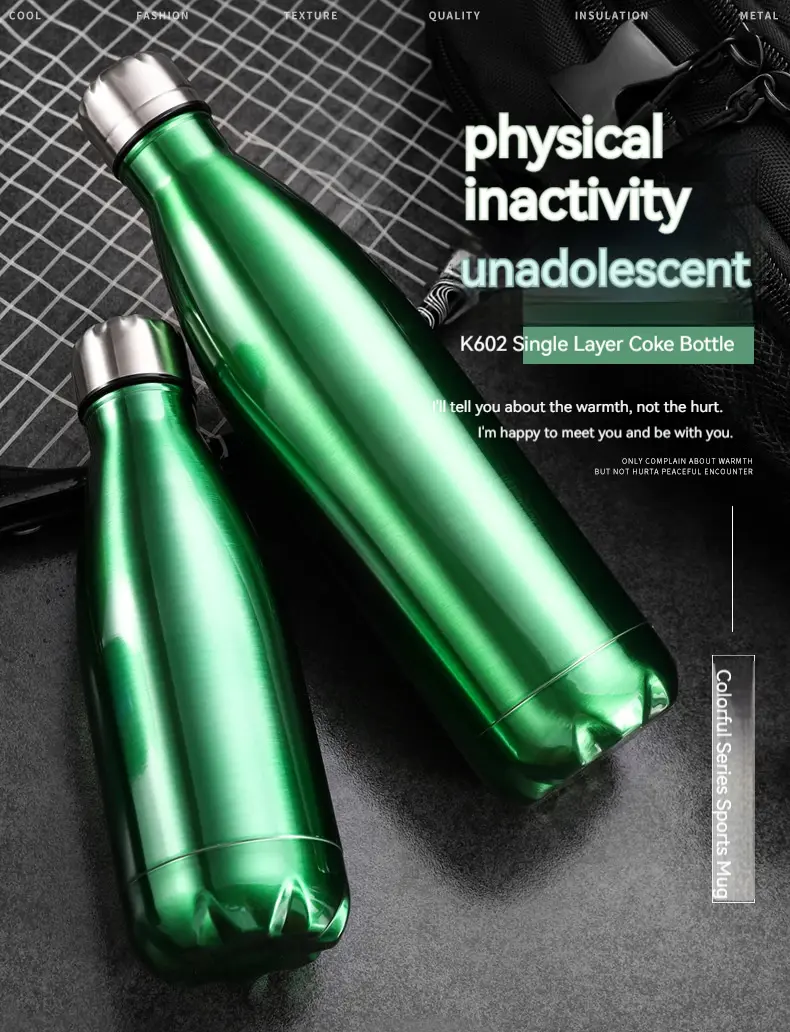

What processes does a stainless steel water cup go through from production to delivery?

The manufacturing of stainless steel water cupsgoes through multiple processes, from raw material preparation to finished product delivery. Each process has an impact on the quality and performance of the final product. The following are the general processes for the production of stainless steel water cups:

**1. ** Raw material preparation:

First, stainless steel raw materials need to be prepared, usually food-grade stainless steel, such as 304 or 316. These raw materials need to meet relevant quality and safety standards.

**2. ** Cutting and shaping:

The stainless steel plate goes through a cutting and forming process, cutting it into pieces of appropriate size and shape for subsequent processing.

**3. ** Molding and Tooling:

Use a forming machine to shape the cut stainless steel sheets. This can be done by stamping, stretching, rolling, etc. to make it into the preliminary shape of the cup.

**4. ** Welding:

The formed stainless steel cup body is welded to ensure its sealing and structural stability. Welding is a critical step in ensuring the structural integrity of your water bottle.

**5. ** Polishing:

The welded water cup is polished to improve the surface gloss and make it more beautiful in appearance. Polishing also helps reduce surface roughness and improves tactile feel.

**6. ** Decoration and Printing:

The water cup can be decorated and printed at this stage, such as spraying colors, spraying patterns or printing trademarks, etc. to meet market needs and brand requirements.

**7. ** Vacuum extraction:

For insulated water cups, vacuum extraction is a crucial step. This ensures a vacuum layer is formed between the double layers of the cup, improving the heat preservation effect.

**8. ** Injection molding or fabrication of lids and accessories:

If the water cup requires a lid or other accessories, these parts can be manufactured through injection molding or other production processes and then combined with the water cup body.

**9. ** Quality inspection:

Conduct quality inspection on finished water cups. This may include visual inspection, dimensional measurements, leak testing, vacuum testing, etc.

**10. ** Cleaning and Disinfection:

Water bottles need to go through a cleaning and disinfection process to ensure the product meets hygiene standards and is clean when users get it.

**11. ** Packaging:

After completing quality inspection and cleaning, the water cups are packaged. Packaging usually needs to comply with relevant standards for domestic and international transportation and sales.

**12. ** Warehousing and Distribution:

Put the packagedstainless steel water cups into storage and arrange delivery to sales channels, warehouses or directly to customers.

The above processes are the main steps in the general stainless steel water cup production process. Each manufacturerand product may have some additional steps or special processes to meet its unique design and market needs.